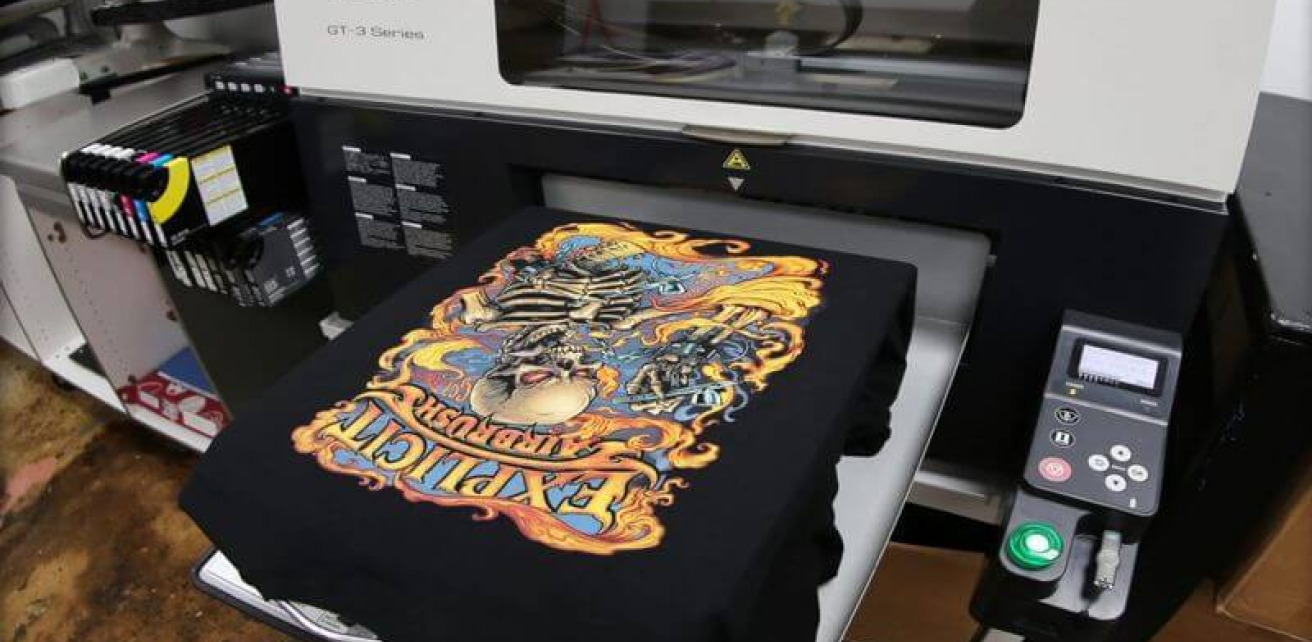

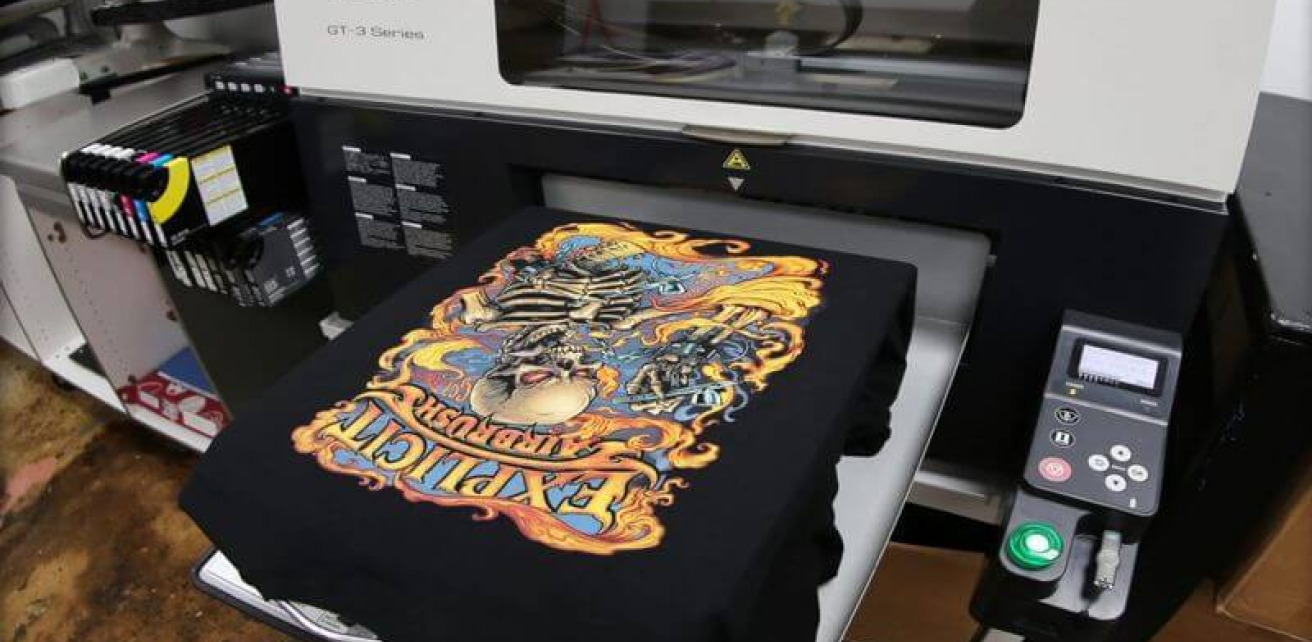

What is Digital Printing?

Digital printing is a method of printing from a digital-based image directly onto a variety of media. It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume laser or inkjet printers.

Why Digital Printing?

Digital printing offers several advantages over traditional printing methods:

Speed: Digital printing does not require the creation of a printing plate, making it faster for short runs and on-demand printing.

Cost-Effective for Small Runs: It's more economical for small print runs because there are no setup costs associated with creating printing plates.

Customization: Each piece can be customized with variable data printing, allowing for unique texts, images, or other information to be printed on each piece.

Quality: Digital printing can produce high-quality prints with a wide color gamut and fine details.

Flexibility: It can be used for various applications, including marketing materials, packaging, textiles, and more.

Pros and Cons of Digital Printing

Pros:

Short Turnaround Time: Quick setup and fast production.

Customization: Easy to print different designs on each item.

Cost-Effective for Short Runs: Ideal for low volume printing.

High Quality: Capable of producing high-resolution prints.

Reduced Waste: Only prints the required amount, reducing waste.

Cons:

Cost for Large Runs: More expensive per unit than traditional printing methods for large quantities.

Color Matching: May not be as precise as traditional methods for certain color requirements.

Material Limitations: Some materials may not be suitable for digital printing.

Durability: May not be as durable as prints made by other methods, depending on the material and use.

Materials Suitable for Digital Printing

Digital printing can be applied to a wide range of materials, including:

Paper: Standard and specialized papers, including glossy, matte, and textured papers.

Cardstock: Thicker paper suitable for cards, invitations, and packaging.

Vinyl: Often used for banners, stickers, and decals.

Fabric: Used in textile printing for clothing, home decor, and custom fabrics.

Plastic: Suitable for labels, signs, and packaging.

Metal: Specialized printers can print directly on metal surfaces.

Ceramic: Used for custom tiles, mugs, and other ceramic items.

Digital printing has revolutionized the printing industry by offering flexibility, efficiency, and high-quality results for a variety of applications. However, it's essential to consider the specific needs of your project to determine if digital printing is the best choice.

UV (Ultraviolet) printing

UV printing is a type of digital printing. UV printing uses ultraviolet (UV) light to cure or dry the ink as it is printed. This method allows for high-quality prints with vibrant colors and sharp details. Here’s a bit more detail on UV printing and how it fits into the digital printing category:

What is UV Printing?

UV printing is a form of digital printing that utilizes ultraviolet light to dry or cure the ink as it is printed. The UV lights cure the printed ink instantly, allowing for immediate handling and additional processing. This technology is particularly useful for printing on non-porous materials.

How UV Printing Works

Printing Process: Like other digital printing methods, UV printing starts with a digital file. The image or text is printed using a specialized UV printer.

Curing with UV Light: As the ink is deposited on the material, UV lights cure the ink instantly. This instant drying process helps prevent the ink from spreading or soaking into the material.

Materials: UV printing can be used on a variety of materials, including plastics, glass, metals, and even wood.

Pros and Cons of UV Printing

Pros:

Immediate Drying: The instant curing process allows for fast turnaround times.

Versatility: Can print on a wide range of materials, including non-porous surfaces.

Durability: UV-cured inks are typically more resistant to scratches, chemicals, and UV light, making them suitable for outdoor use.

Vibrant Colors: Produces high-quality, vibrant prints with sharp details.

Environmentally Friendly: UV inks often emit fewer volatile organic compounds (VOCs) compared to traditional solvent-based inks.

Cons:

Cost: UV printers and inks can be more expensive than conventional printing equipment.

Material Limitations: Although UV printing is versatile, it may not be suitable for all materials or applications.

Complexity: The technology and equipment can be more complex, requiring skilled operators.

Applications of UV Printing

UV printing is used in various industries and applications, including:

Signage: Creating durable outdoor and indoor signs.

Packaging: Printing on packaging materials for a high-end look.

Promotional Items: Custom printing on items like pens, USB drives, and other promotional products.

Decorative Items: Printing on glass, ceramics, and other decorative materials.

Automotive: Custom graphics and decals for vehicles.

UV printing is a versatile and advanced digital printing technology that offers numerous benefits for producing high-quality, durable prints on a wide range of materials.