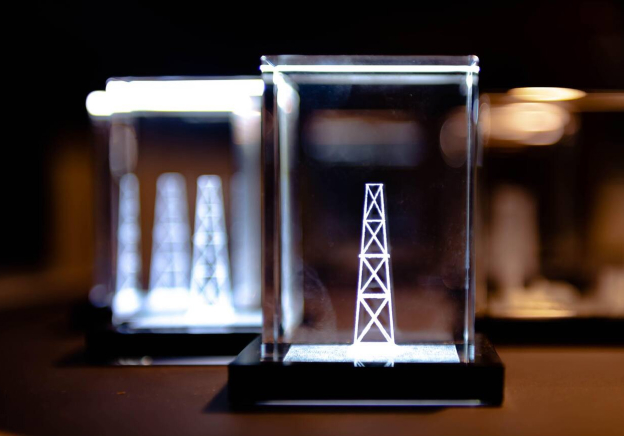

Laser Engraving is a process that uses a laser beam to etch or mark the surface of a material. The laser beam removes the material layer by layer, leaving behind a permanent, high-precision mark. This method offers several advantages over traditional engraving methods such as mechanical engraving or chemical etching.

Here's why laser engraving is often chosen for customized logos:

Precision: Laser engraving provides extremely high precision and detail, allowing for intricate designs and fine lines that may be difficult to achieve with other methods.

Versatility: Laser engraving can be used on a wide range of materials, including metal, wood, glass, acrylic, leather, and more. This versatility makes it suitable for various applications and surfaces.

Speed: Laser engraving is often faster than traditional methods, especially for complex designs. This can result in quicker turnaround times for customized projects.

Cleanliness: Laser engraving is a non-contact process, meaning there is no physical force applied to the material surface. This results in clean and precise marks without any distortion or damage to the surrounding area.

Customization: Laser engraving offers flexibility in customization, allowing for the creation of unique and personalized logos with ease.

Materials suitable for laser engraving logos include:

Metal: Stainless steel, aluminum, brass, copper, titanium, etc.

Wood: Hardwoods such as oak, maple, cherry, as well as plywood and MDF.

Acrylic: Clear, colored, and translucent acrylic sheets.

Glass: Flat glass surfaces such as windows, mirrors, and glassware.

Leather: Genuine leather and synthetic leather materials.

These materials provide good contrast and durability for laser-engraved logos, resulting in professional and long-lasting marks. However, it's essential to consider the specific characteristics of each material and conduct tests to ensure optimal engraving results.

Laser Etching is a process similar to laser engraving but typically involves marking the surface of a material with a shallower depth. In laser etching, the laser beam creates a contrast on the material surface by altering its appearance without significantly cutting into or removing material.

The main difference between laser etching and laser engraving lies in the depth and intensity of the mark:

Laser engraving typically involves removing material from the surface to create a deeper mark with more pronounced depth.

Laser etching creates a surface mark with minimal depth, often altering the color or texture of the material without significantly cutting into it.

Laser etching is commonly used for applications where a subtle mark or contrast on the material surface is desired, such as product branding, identification markings, or decorative designs.

Materials suitable for laser etching include:

Metal: Stainless steel, aluminum, titanium, brass, copper, etc.

Anodized Aluminum: Anodized aluminum surfaces can be etched to reveal contrasting colors beneath the surface layer.

Acrylic: Clear, colored, and translucent acrylic sheets.

Glass: Flat glass surfaces such as windows, mirrors, and glassware.

Coated Surfaces: Materials with coatings or finishes that can be altered by the laser, such as painted metal or coated plastics.

Laser etching is a versatile process that offers precise and detailed marking capabilities, making it suitable for a wide range of materials and applications. However, as with laser engraving, it's essential to consider the specific characteristics of each material and conduct tests to ensure optimal etching results.