Customized Patches

Custom patch decorations offer a versatile and visually appealing way to customize a variety of different products, adding unique and personalized touches to your garments. Whether applied to apparel, accessories, or promotional items, patches provide a distinct means of self-expression and branding. There are rubber/PVC patches, woven & embroidered patches, leather patches, chenille patches, bullion or iron-on patches.

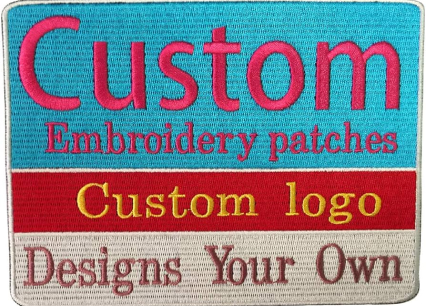

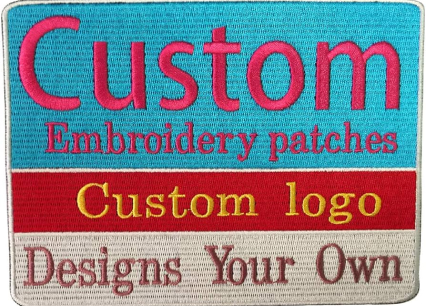

A.Embroidered Patches

1). What is embroidered patch?

The embroidered patch, also called a cloth badge, is an embroidered cloth created using a thread and fabric backing.

2). Benefits of Using Embroidered Patches

Embroidered patches can be a very effective branding strategy for businesses and organizations. Using embroidered patches in marketing strategy can be done in many ways, and it can be put to use not just to promote a product but also to help the brand stand out and appear like a well-established and sophisticated brand. Here are some benefits of using embroidered patches:

Cost-Effective: Embroidered patches are very affordable and attractive. They are best for those looking to run a business marketing campaign within a budget.

Available in All Kinds of Shapes and Sizes: The best quality of embroidered patches is that they can be designed to fit any shape and size.

Durable: Embroidered patches are long-lasting and can last for a long time. Because we use high-quality materials, it can withstand many washes and will not come off or become dull.

Flexibility of Use: Embroidered patches are flexible in terms of their place of application, with many options available. You can apply them to your favorite shirt, jacket, bag, or any accessories.

3). What kind of products can use embroidered patches?

Embroidered patches are often used to customize and adorn clothes, bags, shoes, hats, other accessories, DIY projects, gifts, and costumes

B. Woven Patches

Woven Patches use thinner threads than embroidered patches. Woven patches are made of thread only, and stitched with continuous design to achieve finer detail in the design and text of the patch.

Tips: Woven patches have a smooth surface with no raised texture due to the patch is woven. Woven Patches size can reach up to 7”.

We recommend woven patches If you need to put much information and detail on the patches. Also, For patches with complex edges such as waves, we recommend simple laser cutting (die cutting) rather than embroidering the edges.

C. PVC Patches

The PVC patches are a modern alternative to the embroidered patch. Usually made of durable plastic, PVC comes in different colors that can bring any design to life. PVC patches are waterproof and durable. Because of their durability, PVC patches are great for outdoor applications.

Guess everyone already has heard about PVC a lot more times anywhere. It is a popular material for many industries since it is one of the oldest synthetic materials. It is somewhat compared to be like rubber and is praised because of its undeniable durability. There are hard and soft PVC types, whereas soft PVCs are most likely used. Soft PVCs are admired for their flexibility when it comes to forming and temperature. It can be shaped easily and would not be brittle in time. With all this, no wonder PVC-type patches have become popular.

PVC patches are made by applying pigment and melting at high temperatures for the design and shape. Adding to its admirable attribute is that it is waterproof, it does not fade quickly, and is not easily burned. It has no limits when it comes to design. However, you need to provide a molder first before you can produce it.

In attaching PVC patches, you can paste them on a variety of surfaces. But ideally, most choose to have it with Velcro on clothing.

D. Chenille Patches

Chenille Patches are created using a thick, towel-like material embroidered onto a soft felt background. They are commonly found on varsity jackets or collegiate gear. They can also be sewn onto other outer wear such as caps or hoodies. The chenille patch material and soft felt material is available in a wide variety of colors.

E. Leather Patches

Leather patches are less common than the other patches, but they have a classic appeal and signature look that can’t be achieved in other types.

This type of patch is usually used to attach jackets, jeans, caps, bags, and many more. These are leather cut-outs or shaped fabric that has embossing, debossing, printing, or laser engraving texts and designs on them. Like other types of a patch, it can be sewn on clothing, ironed on, or used with Velcro.

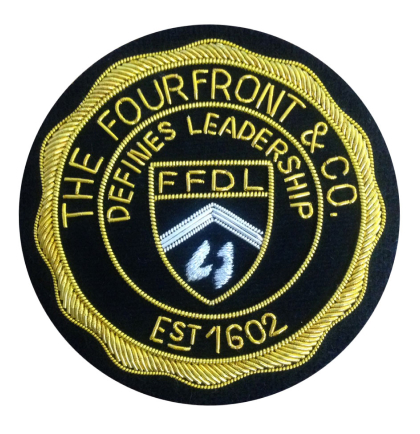

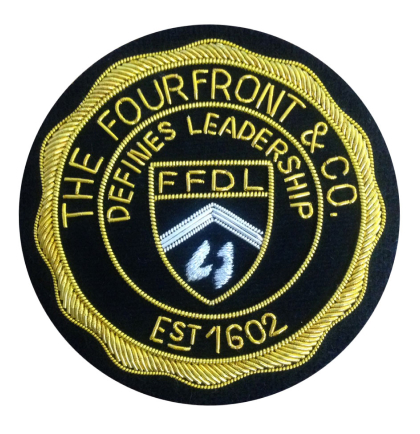

F. Bullion Patches

A Bullion patch is considered a high-end patch. This type of patch is usually used by elite club members, golf clubs, and military people. It is completed with a combination of silk, felt, metallic beads, and velvet materials. They are ideal for simple designs but they give a rich look overall. Because of its metallic and design totality, it also delivers an exclusivity, exquisite and elite feel.

G. Embroidered+Printed patch

Compared with traditional embroidery patches and woven patches, you may feel very strange about printed patches. Printing patches are a big change and innovation for traditional embroidery patches. The process is completely different from embroidery patches, which makes printed patches have unique advantages.

Printed patches can completely copy your photos, and any photo details can be captured to perfectly present themselves in front of you. For example, choose one of your favorite landscapes or even a picture of a star you like, and we can copy it all the same on a printed patch. We can even add some special effects, such as drop shadows and shading, to make it look vivid. And for printed patches, you don’t have to worry about not having the color you want or worrying about its color. You can use any color without any color restrictions.

We all know that if we want to present rich content on embroidery patches, but the size is small, it’s not possible. We can design themes, but for small details, such as small text, embroidery patches are difficult to present perfectly. That is to say if you want an embroidery patch with rich content and complicated details, its size will be limited. But for printed patches, you won’t have to worry about anything. Even small words, they are readable and clearly visible. You can choose any size even if your design is very complicated.

There is another main advantage that should not be overlooked in printing patches, that is, the price is the cheapest. Some people may prefer the appearance of texture, so we suggest that you can choose our embroidery patch. If you want more detailed design patches, you prefer the traditional embroidery process, think about our Custom Woven Patches. But if you don’t want the texture of the look and don’t pursue the traditional patch process, then we suggest you can choose our printed patches. After all, it enjoys high quality and enjoys absolute cost advantages.

Embroidered Patch Backing

There are three main types of backing for embroidered patches: iron-on, velcro, and adhesive backing.

Iron-on Backing

Iron-on backing is also called heat seal as it uses heat to attach the embroidered patch into the fabric. Iron is used to press the patch until it sticks into the material.

Velcro Backing

Velcro backing uses hooks and loops. The loop is sewn on clothes while the hook is sewn to the patch. Velcro backing is often used for police and military patches.

Adhesive Backing

Adhesive backing is the most used type of backing. In this backing, adhesive tape is used to attach the embroidered patch. The process is not long-lasting, so it is only suitable for non-permanent patch attachment. The embroidered patches are ready to iron onto any fabric or DIY materials.